-40%

1974 Yamaha DT360A - 9-Page Vintage Motorcycle Road Test & Tech Article

$ 7.43

- Description

- Size Guide

Description

1974 Yamaha DT360A - 9-Page Vintage Motorcycle Road Test & Tech ArticleOriginal, Vintage Magazine Article

Page Size: Approx. 8" x 11" (21 cm x 28 cm) each page

Condition: Good

YAMAHA

DT360A

Road

Test

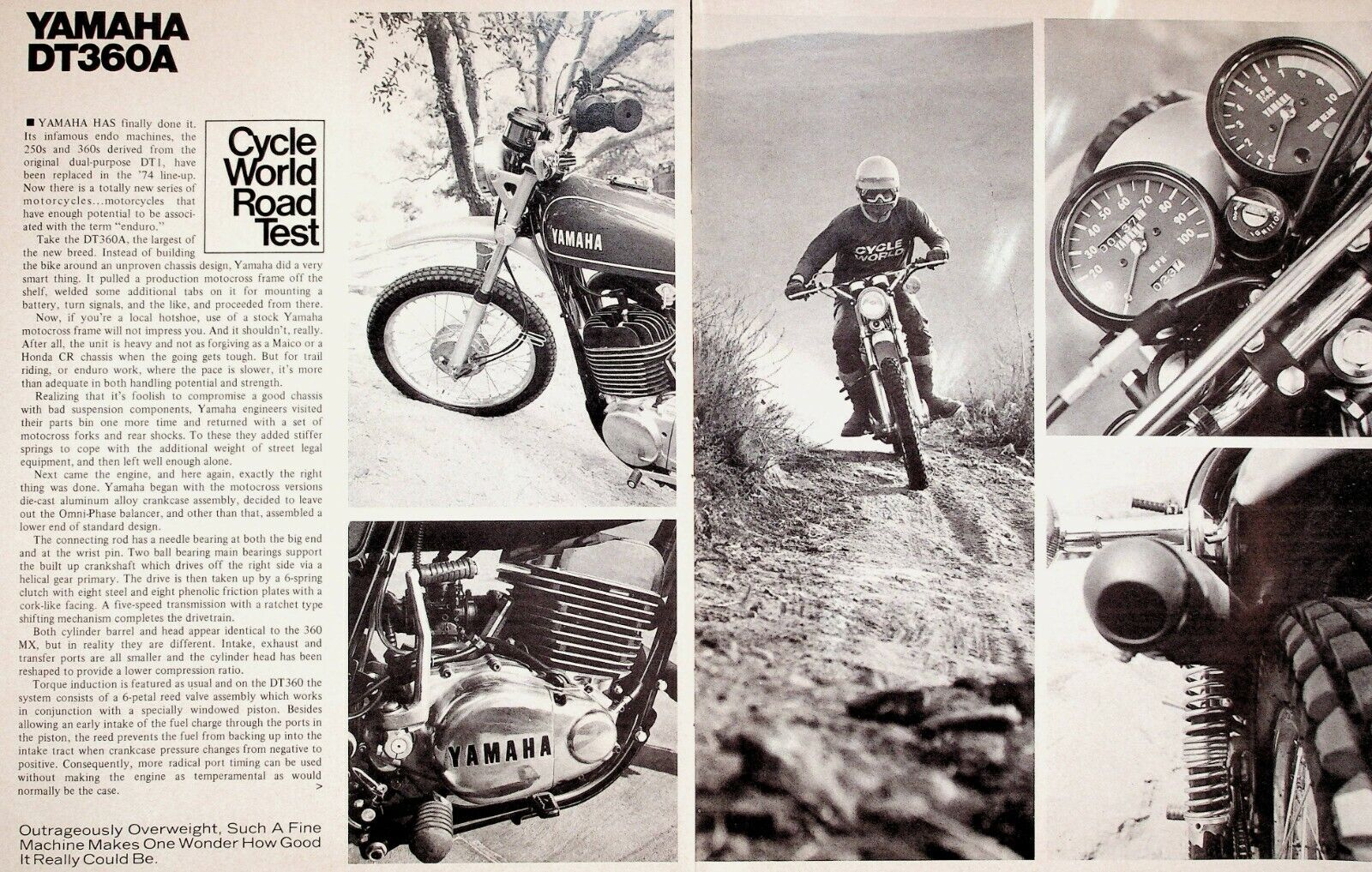

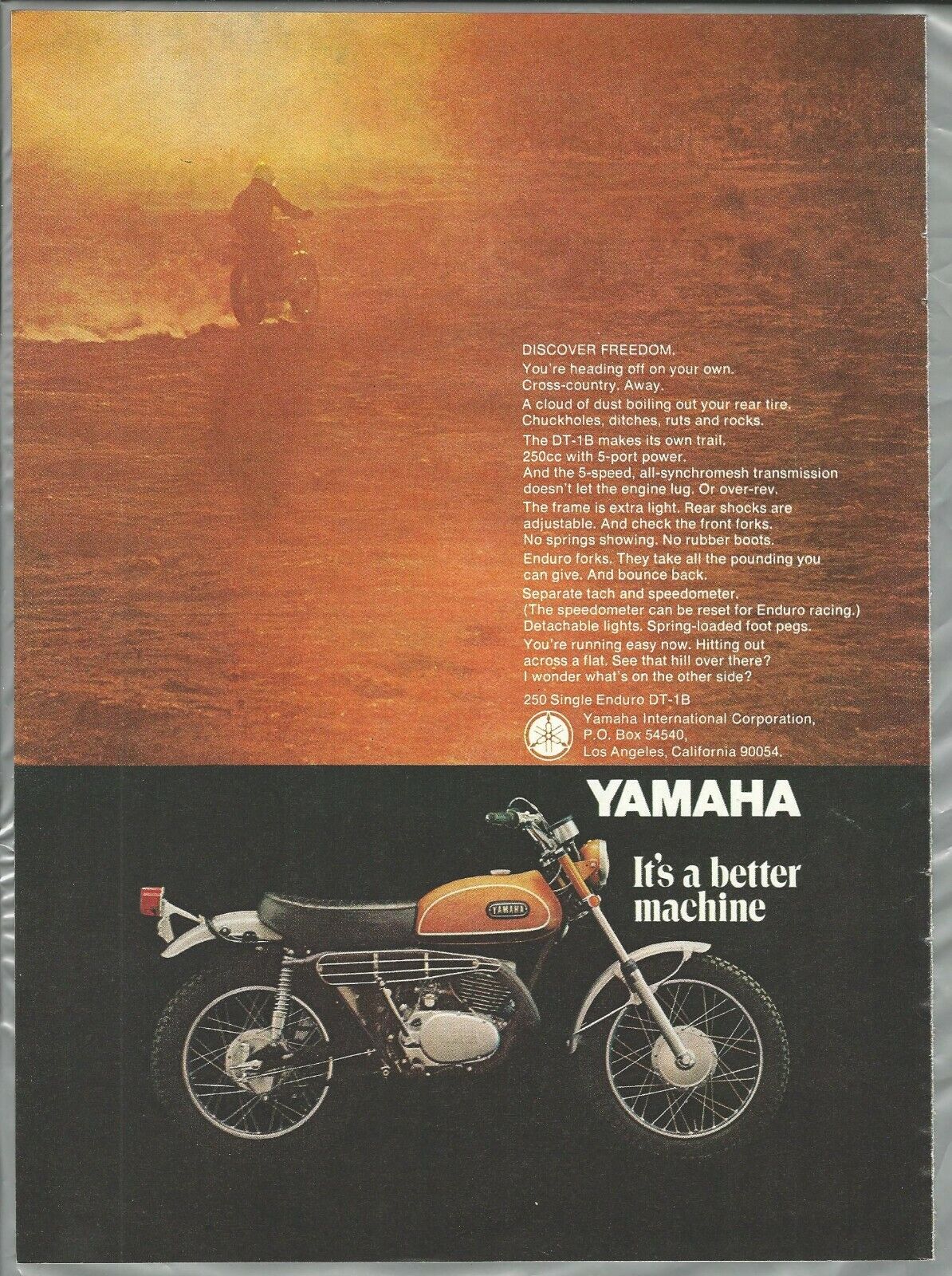

■ YAMAHA HAS finally done it.

Its infamous endo machines, the

250s and 360s derived from the

original dual-purpose DTI, have

been replaced in the ’74 line-up.

Now there is a totally new series of

mo tor cycles... motorcycles that

have enough potential to be associ-

ated with the term “enduro.”

Take the DT360A. the largest of

the new breed. Instead of building

the bike around an unproven chassis design, Yamaha did a very

smart thing. It pulled a production motocross frame off the

shelf, welded some additional tabs on it for mounting a

battery, turn signals, and the like, and proceeded from there.

Now, if you’re a local hotshoe, use of a stock Yamaha

motocross frame will not impress you. And it shouldn’t, really.

After all, the unit is heavy and not as forgiving as a Maico or a

Honda CR chassis when the going gets tough. But for trail

riding, or enduro work, where the pace is slower, it’s more

than adequate in both handling potential and strength.

Realizing that it’s foolish to compromise a good chassis

with bad suspension components, Yamaha engineers visited

their parts bin one more time and returned with a set of

motocross forks and rear shocks. To these they added stiffer

springs to cope with the additional weight of street legal

equipment, and then left well enough alone.

Next came the engine, and here again, exactly the right

thing was done. Yamaha began with the motocross versions

die-cast aluminum alloy crankcase assembly, decided to leave

out the Omni-Phase balancer, and other than that, assembled a

lower end of standard design.

The connecting rod has a needle bearing at both the big end

and at the wrist pin. Two ball bearing main bearings support

the built up crankshaft which drives off the right side via a

helical gear primary. The drive is then taken up by a 6-spring

clutch with eight steel and eight phenolic friction plates with a

cork-like facing. A five-speed transmission with a ratchet type

shifting mechanism completes the drivetrain.

Both cylinder barrel and head appear identical to the 360

MX, but in reality they are different. Intake, exhaust and

transfer ports are all smaller and the cylinder head has been

reshaped to provide a lower compression ratio.

Torque induction is featured as usual and on the DT360 the

system consists of a 6-petal reed valve assembly which works

in conjunction with a specially windowed piston. Besides

allowing an early intake of the fuel charge through the ports in

the piston, the reed prevents the fuel from backing up into the

intake tract when crankcase pressure changes from negative to

positive. Consequently, more radical port timing can be used

without making the engine as temperamental as would

normally be the case.

>

Outrageously Overweight, Such A Fine

Machine Makes One Wonder How Good

It Really Could Be...

14862-AL-7402-08